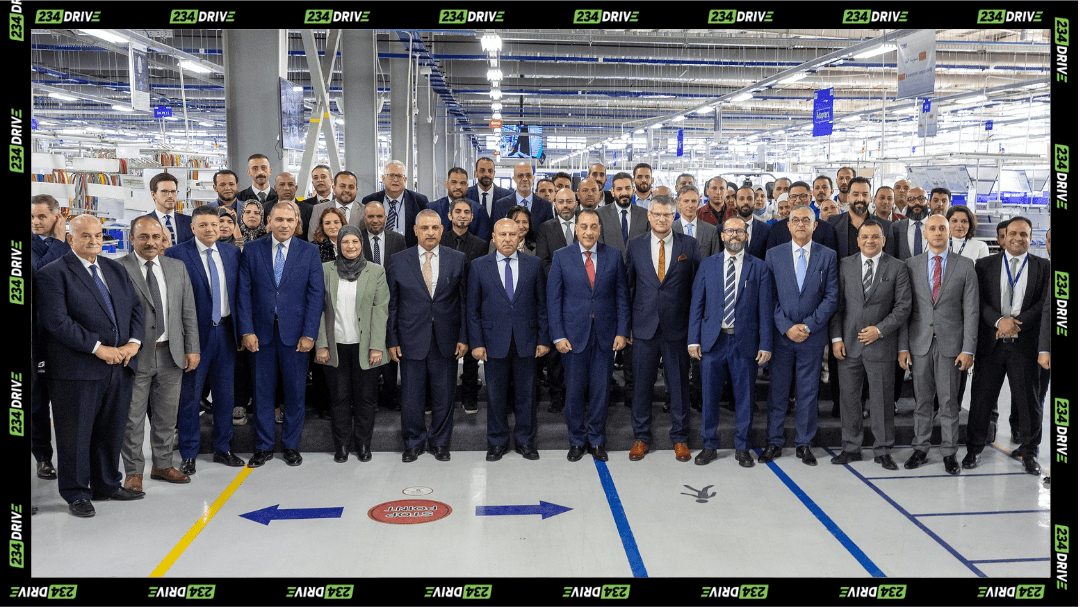

Egyptian officials, LEONI executives, and factory teams pose for a group photo inside the expanded automotive wiring harness plant in Badr City. | Source: Leoni

Egypt has long made its mark in history, and that hasn’t changed even in the present. This week, the African country strengthened its role in the global automotive supply chain as Prime Minister Mostafa Madbouly inaugurated LEONI Egypt’s expanded wiring harness factory in Badr City. The new 14,000-square-metre facility increases production capacity for one of the world’s largest wiring-harness manufacturers and reinforces Egypt’s position as a key hub for components used in both conventional and electric vehicles.

During his tour, Madbouly walked through several production lines and highlighted how Egypt has become a preferred base for global wiring-harness suppliers. He pointed to rising investor confidence, stronger industrial capabilities, and a workforce that has supported major expansions under the national industrial development strategy. The message he echoed all through was that Egypt is not just assembling parts but becoming a strategic link in international automotive and EV supply chains.

Sherief ElDessouky, Chairperson of LEONI Egypt, noted that LEONI now operates in 30 countries and supplies leading global automakers. The Chairperson highlighted that the Egyptian facility now produces about 45,000 wiring harnesses daily through three continuous shifts, making it a core node within the company’s worldwide network. Additionally, LEONI exported over €230 million worth of products in 2024, placing it among Egypt’s top exporters in the free-zone system. To meet growing demand, the company recently secured a 92,000-square-metre plot from the Industrial Development Authority to build a larger industrial complex that will expand output and deepen Egypt’s manufacturing capabilities.

Madbouly’s tour included a stop at a locally built plastic-insulation assembly machine, a key tool in harness production. The prime minister also visited the dashboard assembly unit supplying BMW and Mini Cooper models. Before making his final stop at a specialised line that produces charging harnesses for BMW’s fifth-generation electric vehicles, which officials view as proof that Egypt is gaining ground in high-value EV components.

Egypt Isn’t the Only African Country Stepping Up to Join the Global EV Mobility Chain

It’s more good news for the African continent, as similar shifts are underway in other countries that are using their resources and policy reforms to claim a stake in the electric-vehicle transition. Ethiopia is working to build a full EV value chain anchored by its lithium and cobalt deposits. The plan is to refine minerals locally, assemble batteries, and support domestic EV production so that more of the value stays inside the country. Kenya is moving along an EV complementary path. After years of depending on fully built imported EVs, it is now working to expand its local assembly for electric buses, motorbikes, and compact cars. This approach strengthens local industry and responds to fast-growing transport needs. More importantly, it signals that Africa’s electric-mobility shift is already underway, setting a clear pace that other countries on the continent will not want to be left behind as global EV supply chains continue to take shape.