The long-standing ‘range anxiety’ and ‘charging dread’ that have hindered the mass adoption of electric vehicles may have just met their match in a British engineering breakthrough that triples charging speeds.

British startup Hydrohertz has officially unveiled its Dectravalve technology, a thermal management innovation that promises to slash charging times by up to 68 per cent. Launched in November 2025, the technology is the result of intensive development by a team of former motorsport and power electronics engineers. By tackling the fundamental thermal bottlenecks that force batteries to throttle power, Hydrohertz aims to reduce the standard 10-80 per cent charge cycle from a cumbersome thirty minutes to a mere ten minutes.

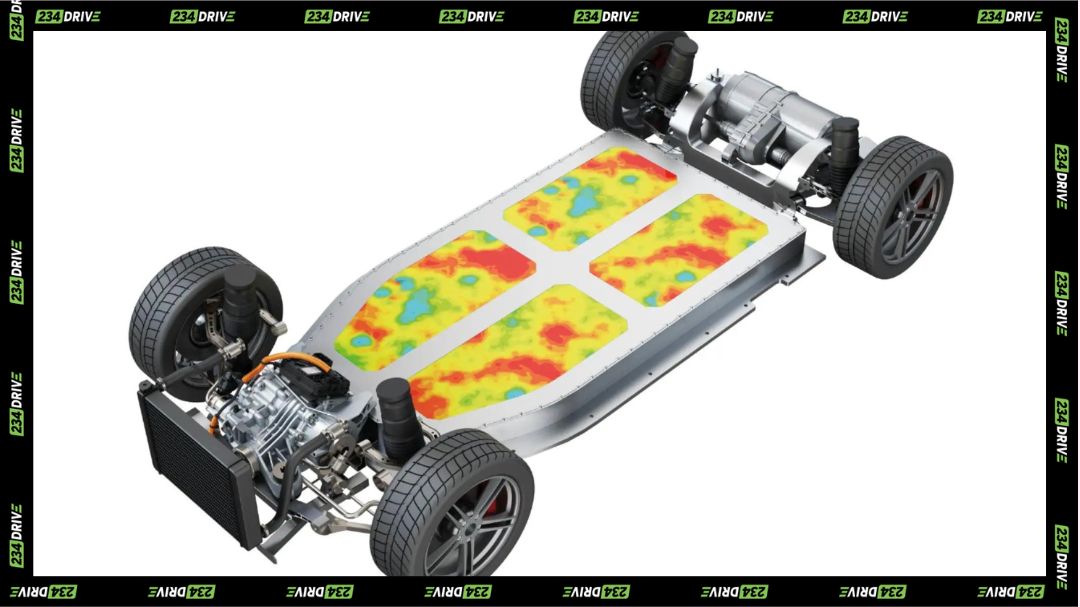

The Dectravalve itself is a marvel of compact engineering, roughly the size of a soda can, which acts as the ‘brain’ of a vehicle’s cooling system. Unlike traditional single-loop systems that cool an entire battery pack uniformly—often leading to dangerous hotspots in the centre and over-cooling at the edges—the Dectravalve employs a zone cooling innovation approach. Using a high-precision stepper motor and a rotary design with concentric cylinders, it can redirect coolant to specific battery zones in milliseconds. This ‘rainbow cooling’ technique ensures that every cell stays within its optimal temperature window, even when subjected to the extreme stresses of a 350kW ultra-fast charger.

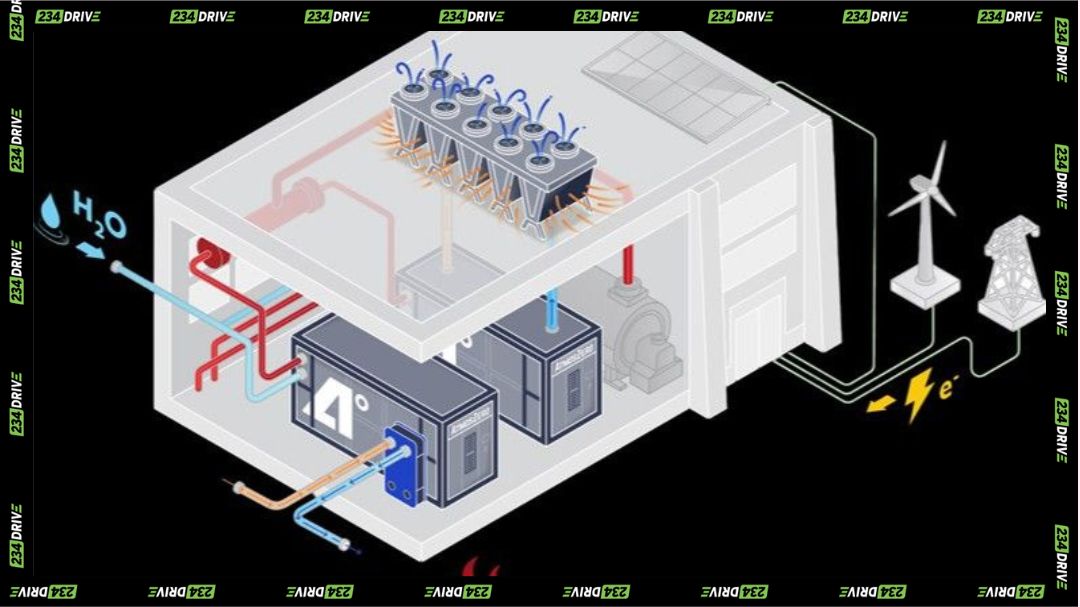

The roles within this technological ecosystem are clearly defined: Hydrohertz provides the intelligent valve and control logic, the vehicle’s existing pumps and heat exchangers provide the physical power, and the battery management system (BMS) provides the data to orchestrate the flow. This integration is designed to be seamless, utilising standard water-glycol coolants and requiring no radical redesign of existing battery architectures. Such advancements in efficiency are crucial for the sector, especially as British vehicle output faces significant historical challenges.

This move signals a decisive shift in the automotive industry from simply increasing battery capacity to breaking charging bottlenecks through thermal efficiency. While the last decade was defined by the race for higher energy density, the next will be won by those who can manage heat most effectively. By extracting more performance from existing lithium-iron-phosphate (LFP) and nickel-manganese-cobalt (NMC) chemistries ‘for free’, Hydrohertz is positioning itself as a critical enabler for carmakers looking to scale their EV offerings without the prohibitive costs of exotic new battery materials.

When compared to the current global landscape, where competitors in China and North America are focusing on massive battery swaps or solid-state experiments, the UK-based Hydrohertz approach is remarkably pragmatic. This technical pragmatism is increasingly important in high-stakes market matchups, such as the Rivian vs Tesla rivalry currently dominating the SUV segment. While others are waiting for the next generation of battery chemistry to arrive in the 2030s, this technology is ready for validation today. Independent tests conducted by the Warwick Manufacturing Group have already confirmed the claims, showing that a 100kWh battery could sustain peak charging rates for significantly longer than traditional systems, with temperature variations kept to a remarkable 2.6°C.

The company’s execution has been swift; following its late 2025 launch, it has already moved into advanced bench testing and is reportedly in talks with several major European and Asian car manufacturers. In the automotive world, the transition from prototype to production usually takes years, but because the Dectravalve simplifies the cooling architecture—removing various hoses and individual sensors—it actually reduces the complexity of the manufacturing process. This efficiency allows manufacturers to focus on other digital enhancements, such as the native audio integration recently pioneered by BMW and Mini.

Hydrohertz’s track record is anchored by its founding team’s experience in the high-stakes world of Formula 1 and high-performance electronics, where thermal management is a matter of millisecond-level precision. This pedigree has already garnered significant interest from clean energy enthusiasts and industry experts alike, who view the Dectravalve as the missing piece of the puzzle for heavy-duty electric transport and high-performance passenger cars.

Ultimately, the success of this British innovation marks a transition from the ‘hype’ phase of electric mobility into the era of fleet-scale practicality that can boost EV range and reliability. As we move closer to the 2030 targets for phasing out internal combustion engines, the focus must shift from how far a car can go on a single charge to how quickly it can get back on the road. Should governments and regulators now treat ultra-fast thermal management as a matter of national infrastructure to ensure the transition to green transport remains on track?