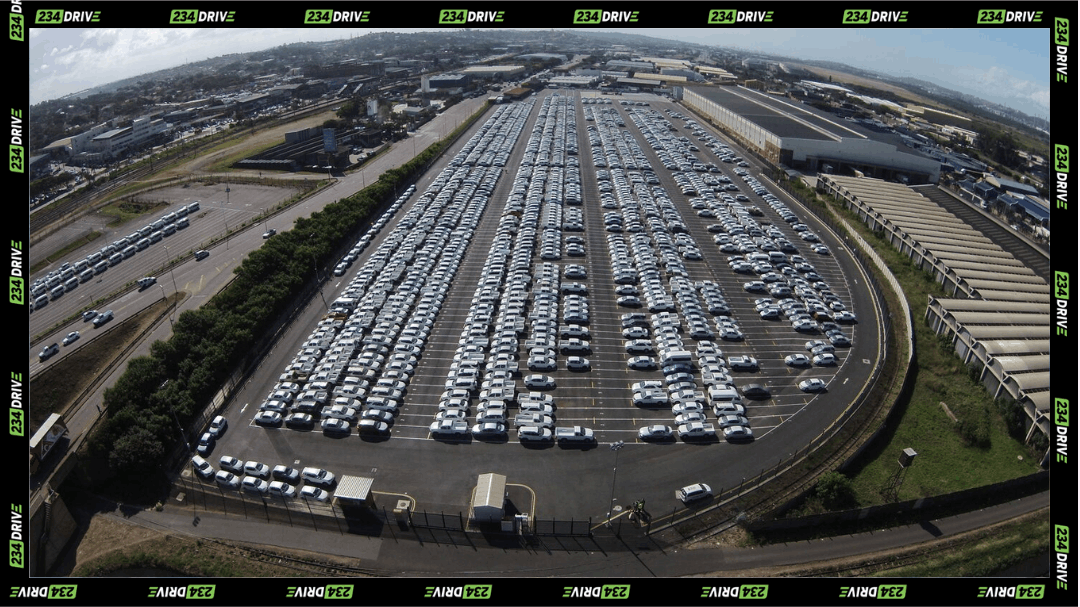

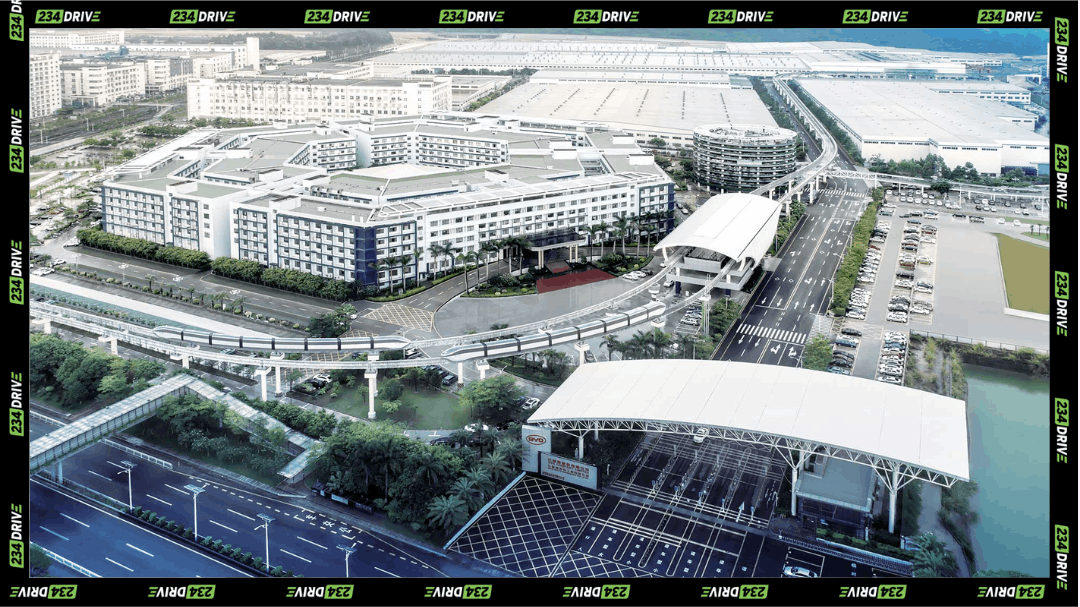

The Kenyan automotive landscape has reached a pivotal juncture as Rideence Africa Limited commits $2.46 million (KSh 320 million) to establish a dedicated electric vehicle (EV) assembly line in Mombasa. This partnership with Associated Vehicle Assemblers (AVA), a subsidiary of Simba Corp, signals a definitive shift from the mere importation of Chinese-built units to a “Born in Kenya” manufacturing model. Announced in early February 2026, the deal facilitates the immediate assembly of 152 EVs from completely knocked-down (CKD) kits, with a target to complete this initial batch by the end of the month. This bold move is expected to catalyse the creation of over 3,000 direct and indirect jobs, reinforcing Kenya’s position as a regional hub for sustainable mobility.

The initiative focuses on two flagship models: the Henrey electric taxi and the Joylong electric minibus. The Henrey units, often referred to as the “Mini Dragon”, are compact hatchbacks offering a range of up to 285 km, perfectly suited for the urban ride-hailing market. Complementing these are the 16-seater Joylong electric minibuses, which target the high-traffic matatu sector with a robust range and 86.1 kWh battery capacity. By transitioning to local assembly, Rideence anticipates a price reduction of up to 25% for these vehicles, making them significantly more competitive against traditional internal combustion engine alternatives.

Under this collaboration, AVA provides the technical infrastructure and skilled labour at its Mombasa plant, while Rideence manages the kit procurement, logistics, and the expansion of the national charging network. This strategic division of labour allows the partnership to scale production to between five and ten vehicles per day. The move also serves to secure Rideence’s supply chain, moving away from the logistical delays associated with fully built imports and allowing for greater customisation to meet the specific demands of East African roads.

Beyond simple assembly, the partnership is a calculated play to capitalise on Kenya’s evolving fiscal environment. By assembling locally, Rideence qualifies for significant tax incentives, including exemptions from the 35% import duty typically levied on fully built units, and a halved excise duty of 10%. Furthermore, the company aims to increase local content procurement to 25% by the end of 2026, with long-term goals of reaching 40-60%. This involves sourcing components like tyres, upholstery, and suspension systems from Kenyan suppliers, thereby integrating the EV sector into the broader national industrial ecosystem.

While the momentum is undeniable, the project faces the scrutiny common to large-scale industrial shifts. Competitors like BasiGo and Roam have already set high benchmarks for local assembly, and analysts point to the ongoing challenge of “range anxiety” and the need for a more supportive policy environment to support a massive influx of EVs. Rideence plans to address this by expanding its current 16 charging stations to 100 by the end of the year. However, the long-term sustainability of the sector will depend on consistent government backing and the ability of local manufacturers to maintain the high quality of components coming from global partners.

This partnership marks a shift from experimental pilot programmes to fleet-scale operations that could redefine public transport across East Africa. As the first batch of Kenyan-assembled electric taxis hits the streets of Nairobi and Mombasa, the industry will be watching closely to see if the promised cost savings and operational efficiencies translate into a permanent market shift.