Electric vehicles (EVs) have shifted the way we think about transportation. Instead of relying on internal combustion engines and fossil fuels, EVs depend on stored electricity. Among all the components inside an EV, the battery pack stands out as the most important part. It determines how far you can drive, how fast the car charges, and often how much it costs.

Why the Battery Pack Matters

The battery pack is the EV’s power reservoir. It stores electrical energy, typically in lithium-ion cells, and powers everything from the electric motor to the onboard systems. Without a capable battery pack, range drops, charging slows and overall performance suffers.

The battery pack holds all the energy the EV needs to run, directly controls how far you can drive and how fast the car can accelerate, and is the single most expensive component of an EV, making up 30–50% of the total cost. Improvements in battery tech drive the entire EV market forward—faster charging, longer range, and lower costs.

Core EV Components and Their Roles

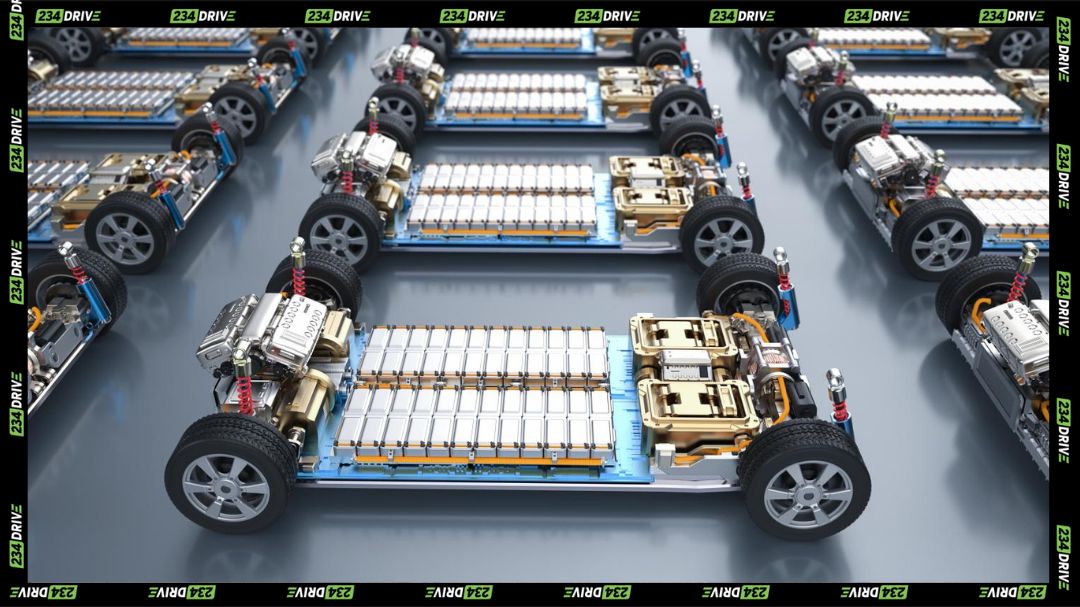

EVs don’t have engines, fuel tanks, or exhaust systems. Instead, they rely on a set of electrical and electronic systems working together. Each plays a role but also depends on the battery pack as the core energy source.

- Energy Storage and Conversion

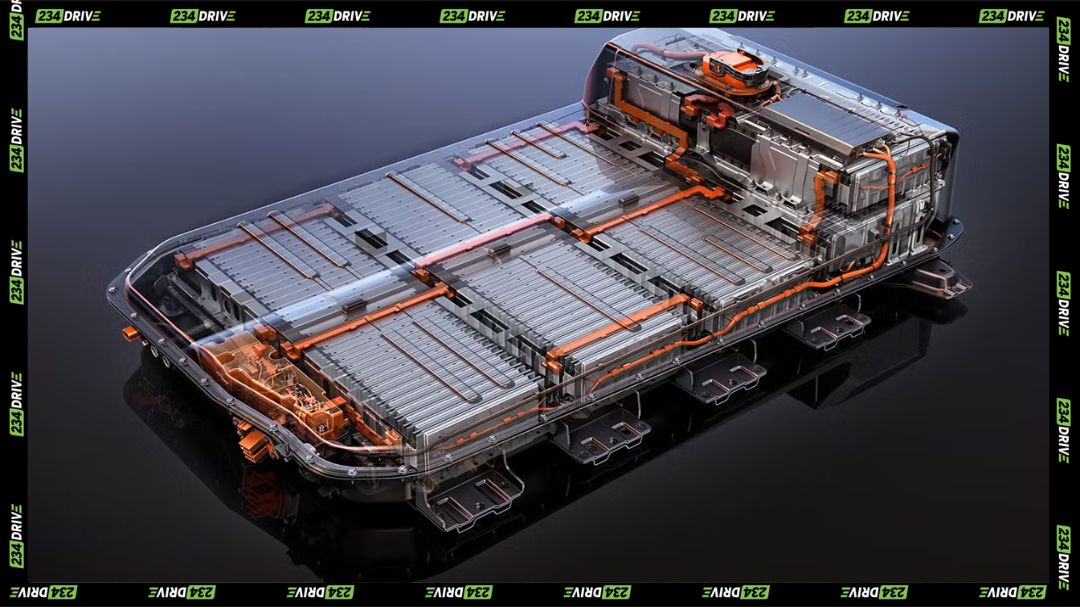

At the heart of every EV lies the battery pack, the most expensive and influential component in terms of range, performance, and safety. It stores the electrical energy required to power the vehicle. Alongside it, the Onboard Charger (OBC) converts external AC electricity into DC for battery charging, while the DC-DC converter steps down high-voltage current to 12V for accessories like lights and infotainment. Together, these ensure the vehicle has a steady, usable supply of power. - Propulsion System

The electric traction motor drives the wheels by converting electrical energy into motion, delivering instant torque and smooth acceleration. Its performance is managed by the inverter, which transforms DC from the battery into AC, controlling speed and torque. The Motor Controller Unit (MCU) further optimises this process by managing power flow in real time, ensuring safe and efficient performance. - Power Management and Distribution

To safely handle the high-voltage system, the Power Distribution Unit (PDU) routes electricity to key components while preventing overloads. The high-voltage wiring harness connects these parts securely, avoiding energy loss or faults. The Vehicle Control Unit (VCU) acts as the brain, coordinating all systems, monitoring diagnostics, and managing overall energy usage to balance efficiency and safety. - Thermal and Comfort Systems

Temperature control is critical in EVs. The thermal management system regulates the battery, motor, and electronics to prevent overheating and extend lifespan. For passenger comfort, the PTC heater and electric AC compressor provide heating and cooling independently of an engine, while the auxiliary battery ensures that non-traction systems like lighting and climate control remain functional even when the main pack is low. - Safety and Energy Recovery

Safety features include the Manual Service Disconnect (MSD), which isolates the high-voltage system during maintenance, protecting technicians. Equally important is regenerative braking, which captures kinetic energy during deceleration and feeds it back into the battery. This not only improves efficiency by extending range but also reduces brake wear, lowering long-term maintenance needs.

Why the Battery Pack Is Often Called the ‘Heart’ of the EV

Unlike a gasoline car, where the engine creates power as needed, an EV depends entirely on stored energy. The battery pack’s size, quality and efficiency affect weight, handling and cost. It’s made of thousands of lithium-ion cells arranged into modules, with a Battery Management System (BMS) that prevents overheating and thermal runaway , thereby keeping the vehicle safe.

The higher the energy density of the battery pack, the more range you get without making the car heavier. Additionally, the battery pack’s advanced chemistry and thermal management can cut down charging times, while its construction must withstand thousands of charge cycles without major degradation.. Battery production and recycling also shape the environmental footprint of EVs.

Other Crucial Components

While the battery pack is the focal point in EVs, the motor and inverter also matter. The electric traction motor converts electrical energy to motion, delivering instant torque for smooth acceleration. The inverter transforms DC from the battery to AC for the motor, also enabling regenerative braking to recover energy. Controllers act as the “brain,” optimising power flow for efficiency and safety.

Some argue the motor is just as critical because it determines driving feel and reliability. Others point to the vehicle control unit as the brain of the car. All these parts work together, but without a strong battery, the system fails.

Technology and Practical Considerations

EV technology revolves around integration. Regenerative braking ties the motor, inverter, and battery together, recovering energy. High-voltage systems support faster charging but demand robust wiring and safety. Maintenance shifts away from mechanical parts to battery health and software updates. Sustainability becomes central as battery production uses lithium, cobalt, and nickel, raising concerns about mining and supply chains.

Future of Battery Technology in EVs

Battery technology is both the backbone and the bottleneck of electric vehicles. It powers range, performance, and safety, yet challenges remain. Freezing weather can cut range by 20–40%, fast charging networks are uneven, and scaling sustainable production and recycling is still difficult. Research into solid-state and sodium-ion batteries promises lower costs, improved safety, and longer lifespans.

The industry is betting big on innovation. Automakers are pushing for faster charging, stronger recycling systems, and new solutions like Vehicle-to-Grid (V2G), which could let EVs power homes and the grid. AI-driven control units will further optimise energy use. Ultimately, the battery pack defines range, cost, and viability, making it the true foundation of electric mobility. As technology advances, batteries will get lighter, cheaper, and more powerful—reshaping the future of how we drive and power our world.