Mitchell 1 is clearly positioning itself for the EV and hybrid era, but the public record doesn’t fully support a very specific claim. On 5th November, 2025, a cloud-based diagnostics platform was launched to cut repair time by 40%. What we do see is a steady run of upgrades, more EV coverage, faster search, cloud estimating rolled out to big repair networks, and tighter integrations with fleet and telematics platforms. Put together, those moves point to the same goal: make EV and hybrid work less painful for shops, especially those outside big cities.

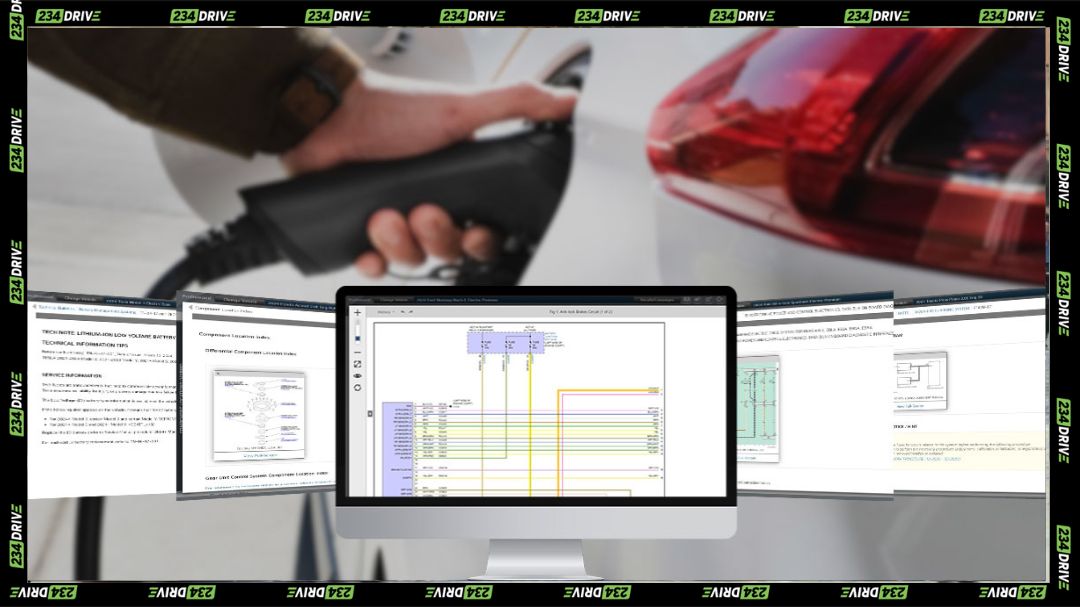

The core of this push still sits inside ProDemand. By late 2024, Mitchell 1 had expanded coverage to about 98% of electric and hybrid vehicles on the road, and that’s the real foundation for everything else. Once technicians can actually find OEM-grade repair procedures, wiring diagrams, high‑voltage safety steps, battery service instructions, and component locations, a shop in a rural town can at least say “yes” to a Tesla‑adjacent job or to a newer plug‑in hybrid. That’s the piece that quietly reduces dependence on dealer networks and opens the door for independent garages to compete.

On top of that content layer, Mitchell 1 has been trimming friction in how technicians find information. The 27th October, 2025 “Did You Mean” upgrade to 1Search Plus seems tiny on paper—just a search correction feature. But, it solves a real problem in EV work: parts and systems have exact names, and a mistyped inverter, on‑board charger, or ADAS calibration phrase can waste minutes. In a busy shop, minutes become hours across the week. So while Mitchell didn’t shout about EVs in that release, the feature clearly helps EV and hybrid diagnostics because the terminology is more specialised and less forgiving.

The 8th September, 2025 launch of Manager SE Inspections pulls in the other direction away from just “finding” information and into “moving” the job through the shop. Digital, multi‑point inspections that feed straight into estimating and customer approvals reduce dead time. That applies to petrol cars, yes, but it matters more for EVs, where customers often need justification for high repair costs or time‑consuming safety steps. A mobile‑friendly report that shows the ADAS or high‑voltage work the shop recommends makes sign‑off faster and keeps the bay turning.

Where things get bigger is on the Mitchell International side with cloud estimating and MSO‑level deployments. On 5th November 2025, Mitchell announced an expanded collaboration with Crash Champions, rolling out Mitchell Cloud Estimating and AI‑driven workflow tools across 650+ centres, including EV‑certified facilities. That’s not marketed as “the EV release,” but it’s exactly the kind of infrastructure EV repairs need: cloud access to OEM procedures, consistent estimating across locations, and AI that can pre‑build an estimate from photos. If a network already has LUXE/EV‑certified centres in the mix, this kind of shared, cloud‑based toolset lets smaller or rural locations lean on the same data and processes as flagship shops. It’s leveling, not just scaling.

A day earlier, on 4th November, 2025, Mitchell 1 also turned up on the Geotab Marketplace, with VOYOLink integrated into Manager SE Truck Edition. That looks like a fleet move and it is, but fleets are where hybrid and electric commercial vehicles will pile up first. Getting real‑time vehicle health, fault codes, and maintenance alerts straight into the shop management system cuts the time between “the vehicle threw a code” and “the shop knows what to do.” Again, there’s no loud 40% number here, but the direction is obvious: shorten the diagnostic loop for vehicles that are becoming more software‑heavy.

Put all of this against the backdrop of Mitchell’s own collision‑repair reporting in 2025. Their Plugged‑In EV Collision Insights noted that EV repairs still tend to run longer and cost more than ICE jobs, though there were signs of BEV claim severity easing and hybrid claims rising. That tells you two things. First, the market is seeing more hybrid/EV volume, so software vendors have to serve it. Second, even in 2025, EV work is still operationally heavierADAS steps, high‑voltage isolation, component calibration. Each incremental update Mitchell delivers—such as auto‑corrected search, integrated inspections, or cloud estimating linked to OEM data—gradually reduces that extra workload.

What’s missing for now is the tidy story of a single, dated launch that suddenly made EV work 40% faster. The public material doesn’t show that. What it shows is a sequence of EV‑friendly improvements across two layers: (1) richer, broader EV/hybrid content in ProDemand and (2) cloud‑delivered workflow tools that MSOs and fleets can deploy everywhere. That combination is what actually empowers rural and second‑tier shops to say yes to a Tesla Model Y heat‑pump issue or to a high‑voltage isolation fault without sending the customer to the city.

Strategically, this puts Mitchell 1 in the camp of vendors building for an electrified aftermarket, not just for dealerships. By keeping the tools cloud‑first, tied to real‑time OEM/diagnostic data, and bundled with estimating and inspection features, they make EV repair capability something you can roll out across 600+ centres, not something that lives in one specialist bay in Los Angeles. That’s the real story in 2025: not a headline launch, but a maturing stack that lets generalist shops handle specialist vehicles.