Just as car brands have their luxury arms, we may soon see the creation and development of multiple auto-aviation divisions.

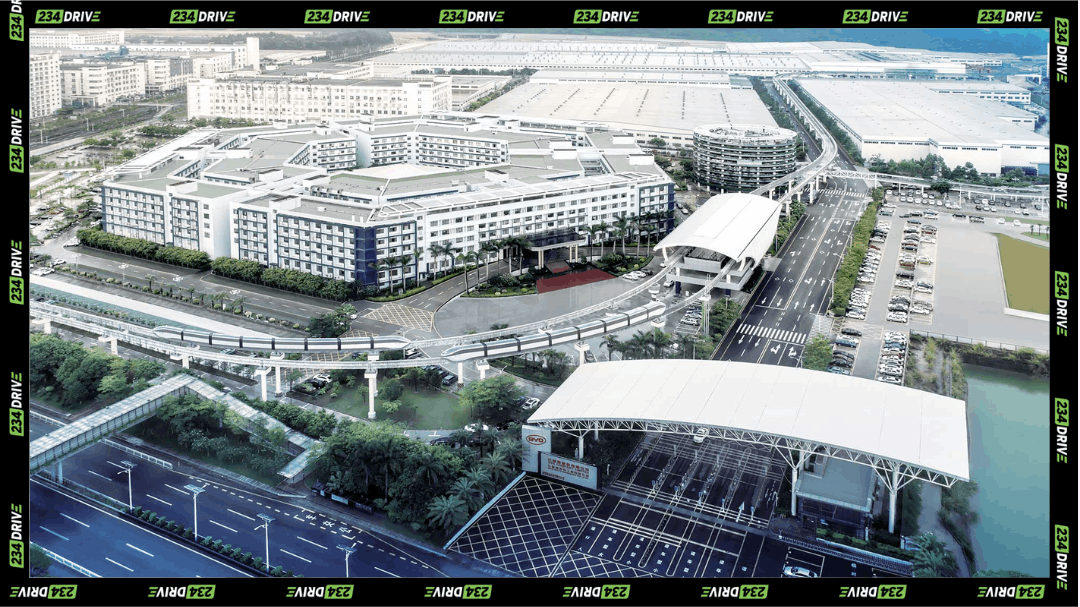

XPENG AEROHT (now Aridge), the flying-car unit of Chinese electric-vehicle maker XPENG, has opened a 120,000 m² intelligent factory in Guangzhou’s Huangpu District and rolled out its first detachable electric aircraft module for its modular “Land Aircraft Carrier”. The plant marks a major step towards commercialising next-generation transport, initially targeting 5,000 units per year and ultimately scaling up to 10,000. It is billed as the largest of its kind and, once fully ramped up, will be able to assemble one aircraft every 30 minutes.

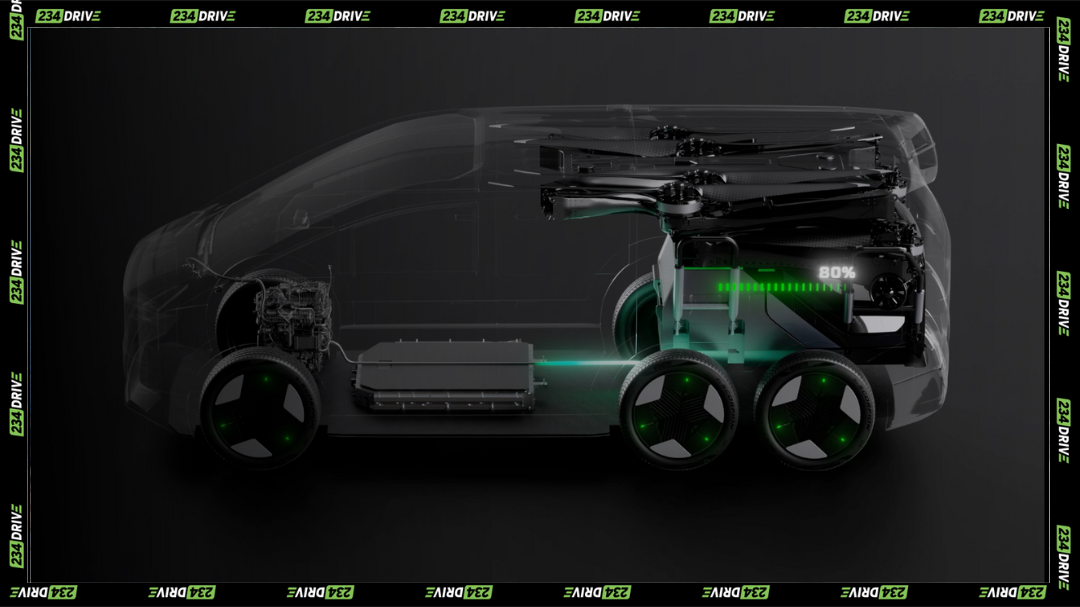

The vehicle pairs a six-wheeled “mothership” ground van with an eVTOL (electric vertical take-off and landing) aircraft module, offering both automatic and manual flight modes, and is road-legal under a standard driver’s licence. Orders approaching 5,000 units have already been secured, with mass delivery slated for 2026.

You can watch the video of the demo flight in October at Dubai to see it in action.

The vehicle is about 5.5 metres long, can be driven on public roads with a standard licence, and can be parked in a regular space. The aerial unit is designed to be transported in the trunk of the mothership, where it can be charged and stored before use.

Analysts regard the move as a milestone in making flying cars commercially viable, signalling a shift beyond prototypes into factory production.

It wouldn’t have been strange if most commuters who were asked which car brand would make the most progress in flying car projects were picking Tesla, but as it is, Aridge has the head start over its competitors in both factory production and customer demand, giving it a potentially stronger foothold in the emerging market.

Can Africa Produce Modular Flying Cars?

While demand for flying-car hybrids hasn’t yet been mapped out in Africa, the continent is steadily proving it can handle projects of comparable industrial scale.

Morocco’s Renault Tanger Méditerranée plant already produces vehicles for both African and European markets, showing how a well-structured ecosystem can sustain large-volume output. In Nigeria, Nord Automobiles’ assembly facility within the University of Lagos demonstrates how innovation and manufacturing can coexist, linking academic research with real-world production.

These examples underline Africa’s growing capacity to manage complex automotive operations, from design to delivery. If this momentum continues, it’s not far-fetched to imagine future mobility technologies, like modular flying cars, finding production footholds on the continent.